Compressor Valves

Product Description

CPI offers a complete line of compressor valves engineered for specific applications with the highest possible flow efficiency and maximum service life. Included are:

- CPI Ring Valves

- Hi-Flo™ Valve

- Radiused Disc Valve

- CPI Plate Valves

- Replaceable Seat Plate

- Dampened Disc Valve

- Poppet Valves

- Indicator Ported Valve

As with every CPI product, quality is the primary concern during valve design and manufacture. Anticipated valve performance is thoroughly analyzed with our proprietary Valve Dynamics Analysis software to ensure long valve life and minimal valve power consumption to satisfy specific compressor operating parameters. Valve engineering utilizes state-of-the-art CAD/CAM to ensure quick accurate designs specifically for your application.

Replacement Parts

To improve or restore the efficiency and performance of virtually all compressor valves, CPI offers a complete line of premium quality replacement parts. These components are engineered and manufactured to assure interchangeability and optimum effectiveness.

Reconditioning/Service Centers

To accommodate our customers local need for quick turnaround, a complete reconditioning service is available at any of CPI’s strategically located service centers throughout the world.

[av_tab_container position=’sidebar_tab sidebar_tab_left’ boxed=’border_tabs’ initial=’1′]

[av_tab title=’HI-FLO™ COMPRESSOR VALVES’ icon_select=’no’ icon=”]

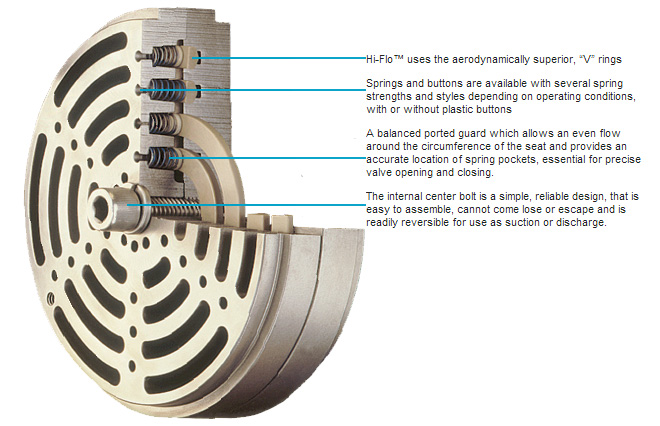

The CPI Hi-Flo™ compressor valve is a high performance valve that takes advantage of a unique sealing element profile. This aerodynamic profile provides:

- Minimum resistance to flow

- Lower pressure drop across valve

- Improved reliability in services with liquids and debris in the gas stream virtually eliminating any foreign matter build up on the sealing surfaces

Performance Advantage

Flat ring designs result in a greater pressure drop because the gas flow through such valves must deflect 90° at two locations to pass around the ring or plate. The Hi-Flo™ design eliminates these drastic changes in direction and efficiently directs the flow of the gas through the valve.

The aerodynamic Hi-Flo™ design reduces valve pressure drop by providing a low resistance to gas flow. Improved compressor performance can be realized since valve power losses and valve capacity losses are directly related to valve pressure drop.

Reliability Advantage

The Hi-Flo™ valves perform extremely well under the dirty gas and liquid slug conditions where flat ring valves typically fail. The aerodynamic angle of the Hi-Flo sealing element deflects any debris or liquid that may be present in the gas stream, virtually eliminating any build-up on the sealing surfaces.

Hi-Flo™ Valve Application Summary

Ring Material

| Recommended RPM Range | Maximum Operating Temperature | |

|---|---|---|

| Nylon | 225° F/ 107° C | |

| PEEK | 425° F/ 218° C |

CPI radiused disc compressor valves are reliable in the oil, gas, petrochemical and air separation industries globally. The CPI radiused disc valve is capable of operating across a wide range of parameters, including discharge temperatures in excess of 200°C/390°F and pressures in excess of 400 bar/6000psi. CPI radiused disc valves are also suitable for sour gas applications.

Each valve is individually designed to match the compressor operating conditions for the application. To achieve this, close cooperation with the operator or compressor manufacturer is involved, including a full review of operating and dimensional data to ensure complete interchangeability with existing valves.

Performance Advantage

The unique radiused profile of the valve discs, which control and seal the process gas as it flows into and from the compressor cylinder, provides a number of important characteristics.

Effective Sealing and Efficient Flow

With radiused discs and matching radii on the seat, discs and seats become self-aligning ensuring good conformability throughout the variation of operating temperatures. Effective sealing between disc and seat is continually maintained resulting in efficient flow.

Radiused Disc Valve Features and Benefits

- streamlined flow enabling free passage of entrained solids and liquids reducing risk of damage, thereby greatly improving reliability

- flow increase due to good sealing

- conformability with seat – under a wide range of operating conditions

- durable thermoplastic discs with no seat damage or wear

- simple internal design – easy to service

- soft-tempered seat and guard -sour gas (H2S) service (NACE)

- suitable for both lubricated and non-lubricated applications

- increased efficiency and savings on power consumption

- less back-flow and often lower process gas temperatures

Sour Gas Applications

All materials of the seat, guard, springs and other internal components are heat treated within the hardness ranges specified by NACE, as the most desirable to resist sulphide stress cracking in H2S – rich gases. This is made possible due to the low impact loads and wear imparted by the thermoplastic discs, in contrast to metal-plate valves, many of which use hardened plates and seats for wear